Although the advanced technology and equipment are a prerequisite for the product quality, the operators’ ideological standards and skill levels must be raised in order to get high-quality products. Every operator shall set up the ideas of “quality first” and shall have high sense of responsibility for quality. Therefore, we often provide on-the-job training to make the operators have a better understanding of theoretical knowledge of production, operating skills, quality control, technological changes and technical standards, thus ensuring that the production can be organized in accordance with the specified requirements and that the product quality can be improved in a steady way.

Quality Inspection and Control

Raw material Inspection includes:

visual inspection, dimensional check, physical & chemical experiments;

Internal inspection and external inspection includes:

dimensional check of steel pipe, visual inspection of welds and the

inspection of other technical requirements;

Non-Destructive Examination includes:

on-line ultrasonic inspection, manual ultrasonic inspection, real-time image formation X-ray test, and X-ray test;

Final inspection:

includes final check of the steel pipe, the review of all the results of the previous inspections.

We evaluate and record all inspections in accordance with the testing results and product specifications to ensure the quality of finished products. All records are maintained in accordance with the specified requirements to look up them in the future.

Main Production and Testing Equipments

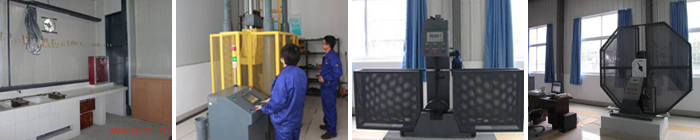

On-line ultrasonic inspection system Industrial television monitor system

φ325mm~φ1820mm S

hydraulic machine |

φ325mm~φ2600mm

hydraulic machine |

Steel pipe hydrostatic

testing |

Pipe end radiographic

testing |

|

Pipe body radiographic testing |

Ultrasonic testing control room |

Off-line ultrasonic Inspection

system |

Steel pipe continuous UT testing |

|

Darkroom

|

Drop hammer tester

|

300J impact machine

|

600J impact machine

|

|

Multi-functional tensile tester

|

Metallurgical microscope

|

Atomic spectrophotometer

|

|

Vickers hardness tester

|

Charpy impact testing specimen calibrator

|

Broaching machine of charpy impact testing specimen

|

low temperature sink for charpy impact testing specimen

|

Charpy impact testing specimen processing equipments